AI image generation without copyright infringement

Discover how to create a Creative Commons dataset for training AI image generation models without copyright infringement. Learn about effective methods and tools for scalable data collection.

Success starts with people. In times of overwhelming change, your teams deserve a partner that empowers them. Meet our minds, the real intelligence behind ML6 — designed to amplify yours.

Stop buying solutions, generate them, and own them. We’re building the platform that spawns agents to do work for you. From enterprise-scale systems to tailored industry and departmental applications, we help you transform the way you work today.

Experience the power of AI for your business through our client cases & testimonials. These stories aren’t just case studies; they’re proof that bold ideas, the right people, and a little AI magic can change the game.

This is where breakthrough ideas emerge and your inner innovator is awakened. Get inspired by the best of ML6's insights and the minds shaping the future of AI.

Success starts with people. In times of overwhelming change, your teams deserve a partner that empowers them. Meet our minds, the real intelligence behind ML6 — designed to amplify yours.

Stop buying solutions, generate them, and own them. We’re building the platform that spawns agents to do work for you. From enterprise-scale systems to tailored industry and departmental applications, we help you transform the way you work today.

Our engineers partner with the world’s leading technology providers to deliver robust, scalable & sovereign solutions.

Experience the power of AI for your business through our client cases & testimonials. These stories aren’t just case studies; they’re proof that bold ideas, the right people, and a little AI magic can change the game.

This is where breakthrough ideas emerge and your inner innovator is awakened. Get inspired by the best of ML6's insights and the minds shaping the future of AI.

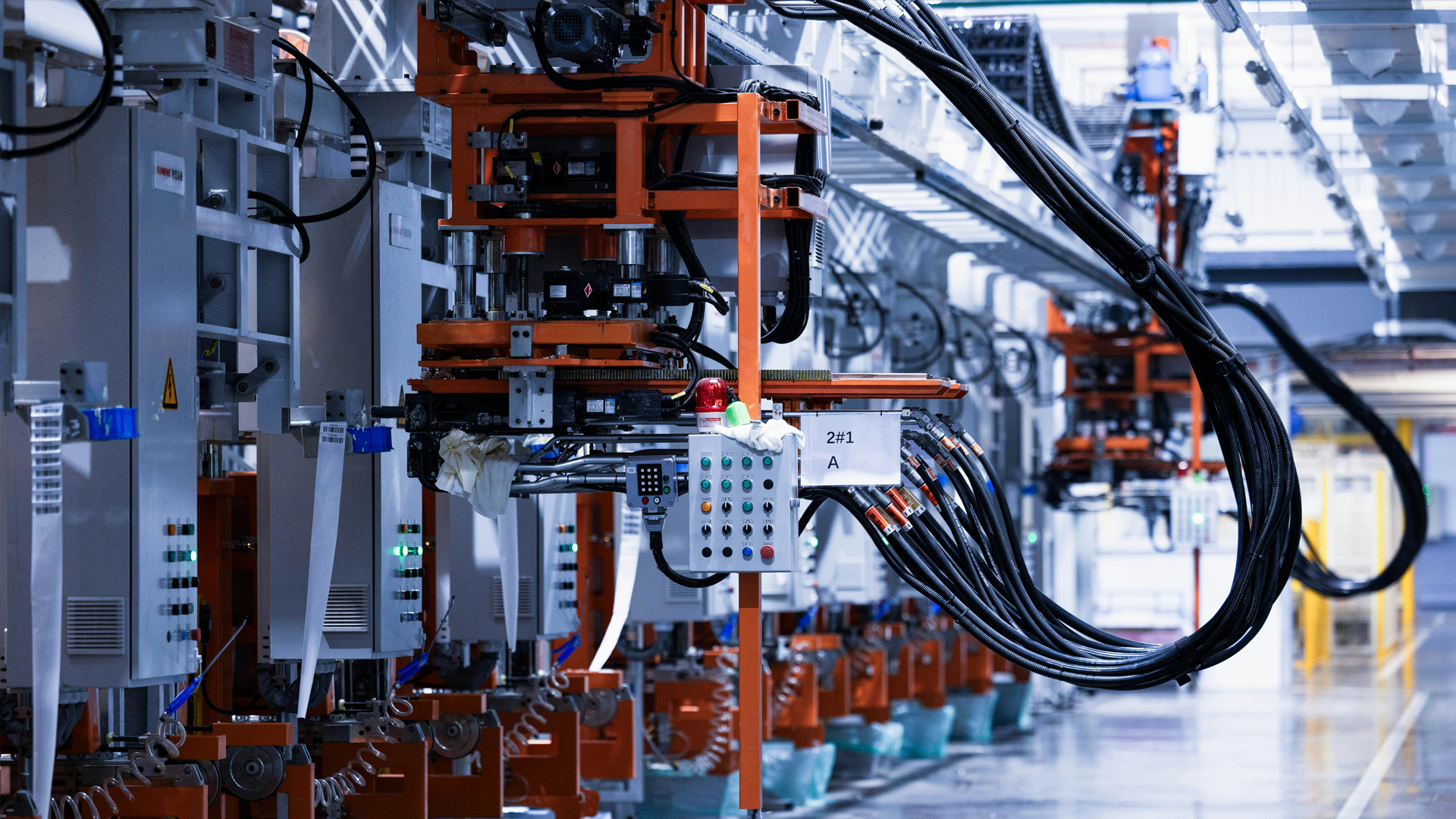

Manual inspection is slow, costly, and prone to human error. Traditional systems require excessive technical overhead and often fall short. ML6 Vision AI changes the game—bringing proven accuracy, scalable automation, and cost efficiency. Built on a decade of applied AI research and reusable ML building blocks, it plugs seamlessly into your production line to deliver results today and adapt to tomorrow’s demands.

of revenue is the cost associated to poor quality.

changeovers typically require manual interventions to control quality

of respondents find in-house ML projects in manufacturing too slow to deliver value.

You need results, not technical overhead. ML6 Vision AI delivers exactly that: a streamlined, future-proof solution that boosts quality and process control without piling up technical debt. Whether you’re optimizing non-core production or scaling enterprise-wide, we partner with you to unlock measurable business impact—fast, reliable, and built to last.

| Traditional Computer Vision | Vision AI | |

|---|---|---|

| Robustness & variability | ⚫ | ⚫ ⚫ ⚫ ⚫ |

| Need for expert knowledge | ⚫ ⚫ | ⚫ ⚫ ⚫ ⚫ |

| Set up | ⚫ ⚫ ⚫ ⚫ | ⚫ ⚫ ⚫ |

| Processing power | ⚫ ⚫ ⚫ ⚫ | ⚫ ⚫ ⚫ ⚫ |

Manual inspections are prone to error, slow, and vary between operators.

Rigid vision systems that can't adapt to new products or defect types.

Difficulty steering processes in real-time based on inspection insights.

Internal AI projects that are too slow or never make it past pilot.

Generic tools that don’t meet the specific needs of your factory.

Fewer rejects, returns, and quality issues ensure higher satisfaction and trust.

Proven modular components enable deployment in weeks, not months.

Reduced labor, rework, and downtime, deliver measurable savings and productivity gains.

Accurate defect detection, less waste, no technical debt, and easy roll-outs across lines deliver sustainable growth.

We either work with your existing hardware set-up or provide, install and monitor the hardware to capture the images of your products, fitted to your needs.

Our ML core processes the captured images using a custom model to detect or classify the products according to your use case.

We integrate with your programmable logic controllers (PLC’s) to communicate the inspection results.

We show production metrics on standard reports and dashboards.

We provide maintenance and support for the solution to guarantee security patches and future functionality upgrades

Your solution is built on scalable, battle-tested modules we’ve successfully applied across industries.

AI engineeringWe reuse components to lower costs, and you only pay for the building blocks you actually need.

Our approachYou continuously benefit from the fast-paced AI/ML advancements we pilot and co-develop with our clients —without the burden of in-house development.

Why choose ML6With us, there’s no "that’s not part of the product vision” and no awkward “we don’t integrate with that.” Our AI is built the way your company actually runs, not the way a product manager thinks it should. Every solution is tailor-made to fit your strategy and company like a glove—no compromises, no roadblocks, no missed opportunities. Just the exact intelligence your organisation needs to move faster, smarter, and stronger.

Stay in the loop with stories from our team, success cases from our clients, and news on what we’re building behind the scenes. Whether it's a deep dive into the latest in AI, a behind-the-scenes look at a real-world implementation, or product updates we’re proud of — here’s what’s been happening lately.

Discover how to create a Creative Commons dataset for training AI image generation models without copyright infringement. Learn about effective methods and tools for scalable data collection.

Explore the principles, benefits, and applications of Stereo Vision, Structured Light, and Time of Flight in optical 3D acquisition. Learn which method suits your needs best.

Discover how AI can revolutionize product photography by generating professional images from amateur photos, saving time and costs for businesses of all sizes.