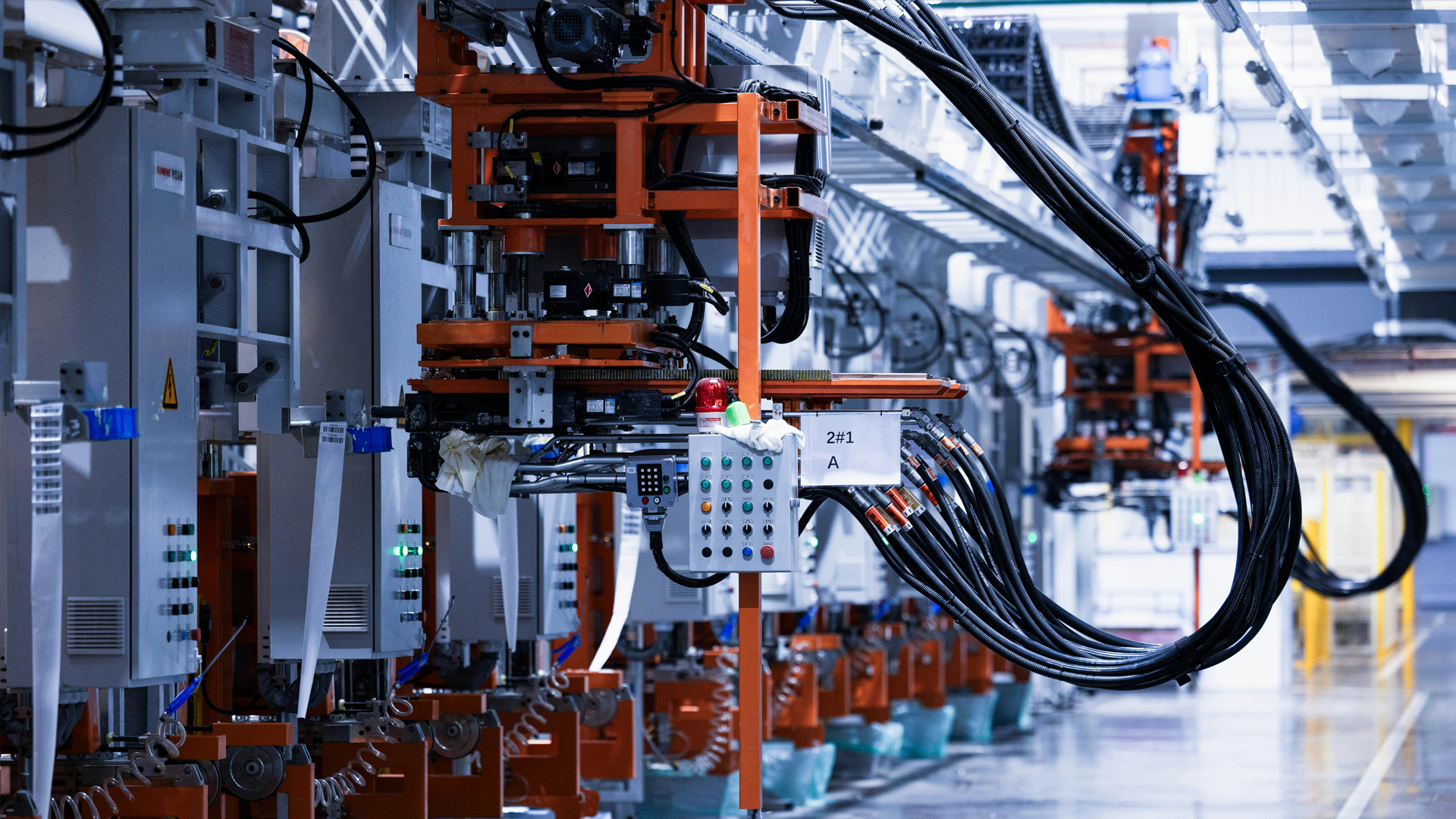

Procurement in the industrial sector is increasingly complex, with raw material volatility, shifting consumer demand, ESG requirements, and supply chain inefficiencies driving constant pressure. AI provides the tools to stay ahead by:

Smarter Sourcing Decisions – Identify the most reliable, sustainable, and cost-effective suppliers based on performance, risk, and compliance.

Dynamic Cost Optimisation – Forecast raw material fluctuations, optimise purchase timing, and prevent overspending.

Waste Reduction – Detect inefficiencies across the value chain, from packaging to logistics, and highlight opportunities to reduce waste without compromising quality.

Stronger Compliance – Automate checks against regulatory, sustainability, and data-security requirements (e.g. GDPR, ESG, EU AI Act) to reduce supplier risk and ensure procurement decisions meet the highest standards.

Smarter Governance – Increase transparency and accountability by monitoring supplier practices, identifying risks early, and ensuring responsible sourcing at scale.